From Best Practice To Next Practice

Today was the final day of the 2nd Annual Global Smart Manufacturing Summit in Berlin, Germany. I really valued the time to get to know business and industry leaders from around the world. I was reminded of what my good friend Kevin Eikenberry and I used to talk about a lot – when we look at the differences between different industries (eg. manufacturing vs. education), we see about 90-95% of our issues being the same and about 5-10% different. What I mean here is that many of the challenges and roads to improvement are the same. Think about it, we all have responsibility in finance, HR, facilities, and customers. If we break that down further, we all have one of the same groups within the customer category – employees. Now, I get it; our employees are our competitive advantage, but employees are still a customer to be taken care of at the highest level.

Today was the final day of the 2nd Annual Global Smart Manufacturing Summit in Berlin, Germany. I really valued the time to get to know business and industry leaders from around the world. I was reminded of what my good friend Kevin Eikenberry and I used to talk about a lot – when we look at the differences between different industries (eg. manufacturing vs. education), we see about 90-95% of our issues being the same and about 5-10% different. What I mean here is that many of the challenges and roads to improvement are the same. Think about it, we all have responsibility in finance, HR, facilities, and customers. If we break that down further, we all have one of the same groups within the customer category – employees. Now, I get it; our employees are our competitive advantage, but employees are still a customer to be taken care of at the highest level.

Organizational Commitment

The first session this morning was about initiatives and organizational commitment. As a believer in learning organizations, I was really enamored by the discussion of organizational commitment. This thinking really fits with a lot of the Gallup® research I have been studying around employee engagement. When we discuss organizational commitment, we are talking about the bond employees experience with their organization. Broadly speaking, we know employees who are committed to their organization generally feel a connection with their organization, feel that they fit in, and believe they understand the goals of their organization.

Next Practice

Next Practice

One of the session titles this morning was “From Best Practice To Next Practice.” I really appreciated this session because we talk a lot in education about “best practices,” but really it is about making the right choice and implementing the next practice. Good or bad, I tend to be the one looking for the next practices. Really, that is what this entire discussion was about for the global leaders here: what are the next practices.

Convergence

Then, it comes down to convergence. How do we take several sources of independent data and bring them together to develop strong conclusions? In education we call this using “multiple data points.” I don’t think we do the best job of bringing all the data points together. For example, this week I was reading and article about teacher pay and how it was decreasing. I question if we have been properly converging HR, financial planning, and student data in a way that would inform what we have been paying our teachers in Indiana. I’ll let you grapple with my comment here, but you get the point.

Problems

One of the comments that I loved most today was, “We shouldn’t be talking about the problems of today, but the problems of tomorrow.” This is so true! This means in education we need to be looking several years out as to what business and industry needs. We also need to think about what our execution model will be for making sure our students have the skills necessary to meet the needs of the workforce. A few phrases/questions coming from the global manufacturing leaders that jumped out at me were:

- What data is coming from where?

- How do you use your data?

- Appropriate levels of (you fill in the blank here)

- Move from reactive to predictive and preventative

Outcomes

All of this discussion has made me an hinkeven bigger believer in us (both Indiana and the United States) needing to move to a strictly outcomes based school accountability system. We could then, truly in partnership with business/industry and higher education, determine what transferable skills students need and have coming out of high school. Then we can match those transferable skills to outcomes that the students needs to accomplish. Here are some examples and outcomes:

- industry certifications

- 4 year degrees

- Associate degrees

- Trade school

- Joining the military

- Meaningful employment

At a time when our state has 75,000 jobs per year going unfilled because there are not skilled workers to take those jobs, we need to be thinking about the outcomes for our students. Thus the skills gap of only 42% having any kind of post-secondary preparedness versus the 75% needed.

If we are going to have our students ready for the workforce we will need to:

- Teach students in a real world and relevant context

- Enable, encourage, and stimulate students to be curious

- Teach students how to fail and that it is o.k. to fail

- Engage students in career exploration activities at a young age

- Determine the transferable skills needed to have students ready for today’s jobs

- Teach students to be disruptors

- Provide pre-apprenticeship, apprenticeship, and work based learning internships

Business and Industry engagement in education programs not only prepares students with the skills they need for careers, but it also contributes to the development of clearly developed career pathways that lead students to careers after graduation.

What Does Industry 4.0 Mean?

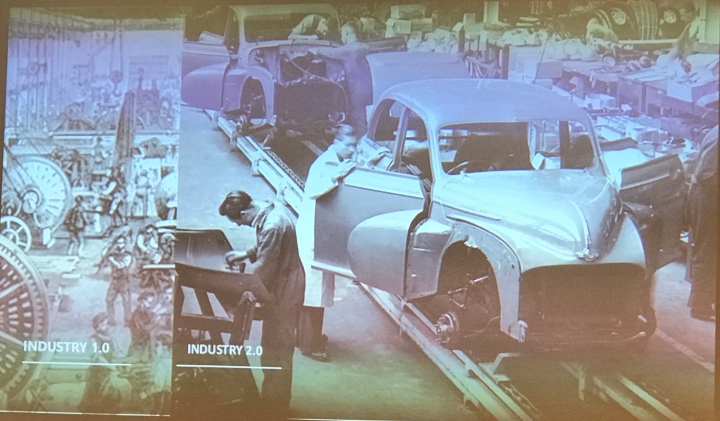

Today, I had the honor of being in attendance at the 2nd Annual Global Smart Manufacturing Summit in Berlin, Germany. One of the topics we grappled with was of what does Industry 4.0 mean? Ron Zahavi, Chief Strategist for IoT Standards and Consortia, Microsoft Corporation did a great job of walking us through some history.

Today, I had the honor of being in attendance at the 2nd Annual Global Smart Manufacturing Summit in Berlin, Germany. One of the topics we grappled with was of what does Industry 4.0 mean? Ron Zahavi, Chief Strategist for IoT Standards and Consortia, Microsoft Corporation did a great job of walking us through some history.

Industry 1.0

This is the first industrial revolution:

- Technology such as wheels and engines replaced artisans

- Child labor laws had to be introduced to prevent abuse

Industry 2.0

- Assembly lines allowed workers to be turned into consumers

Industry 3.0

- Lean Processes improved the quality of products

- Advent of computer use

- Robots reduced mistakes and improved productivity and safety, but began replacing people

Industry 4.0

- Big data and analytics

- Autonomous robots

- Simulation

- Horizontal and vertical system integration

- The industrial Internet of Things (IoT)

- Cybersecurity

- Additive Manufacturing/Advanced Manufacturing

- Augmented Reality

Interestingly, in all these cases technology and mechanization are involved, but in the revolutions of Industry 1.0, 2.0, and 3.0, I wonder if we forgot how important people are. We must remember as we navigate Industry 4.0 that people are more important that the devices and technology.

In my world of educating young scholars and creating education policy, we have a responsibility to make sure as we move to Industry 4.0 to put people at the forefront. We do not want to make the same human mistakes with 4.0 that we made with the first three revolutions.

I really believe more than ever that we must make sure that we create space for industry to do as much of the training of our students as possible. Industry is in a good position to do this. What we have to do, though, is identify the transferable skills students need and institutionalize those skills in the framework of the internship learning being done in partnership with industry. This is crucial because of the mobility of our students.

We must be educating our students on the new things being done with Industry 4.0, but must also be educating them on the benefits. In other words, answering the question: How does this make life easier? Not just always pointing to financial improvement and the bottom line. We must begin to develop a workforce made up of the right quantity and right quality of workers. The skills we are preparing students with must match the needs of the workplace.

Industry 4.0 will require new skill sets, and manufacturers will need to attract the right talent. This may involve partnering with k-12 schools to train students. Existing training programs may need to be expanded to include new technologies that are introduced to the marketplace. Manufacturers also need to recruit for Industry 4.0, which may differ from how they have done it in the past. Both business and industry and education will need to stop all focus being on qualifications determined by degrees and certificates, companies should recruit for capabilities to succeed. These capabilities will include specialized skills.

For us to compete during Industry 4.0, it will require us to conduct constant iteration and be flexible. It’s not about buying software or purchasing a curriculum and then watching it all play out. To compete in Industry 4.0, the education sector and manufacturers must be flexible and agile in the face of change, and, most importantly, partner together.

Learning to Do, Doing to Learn!

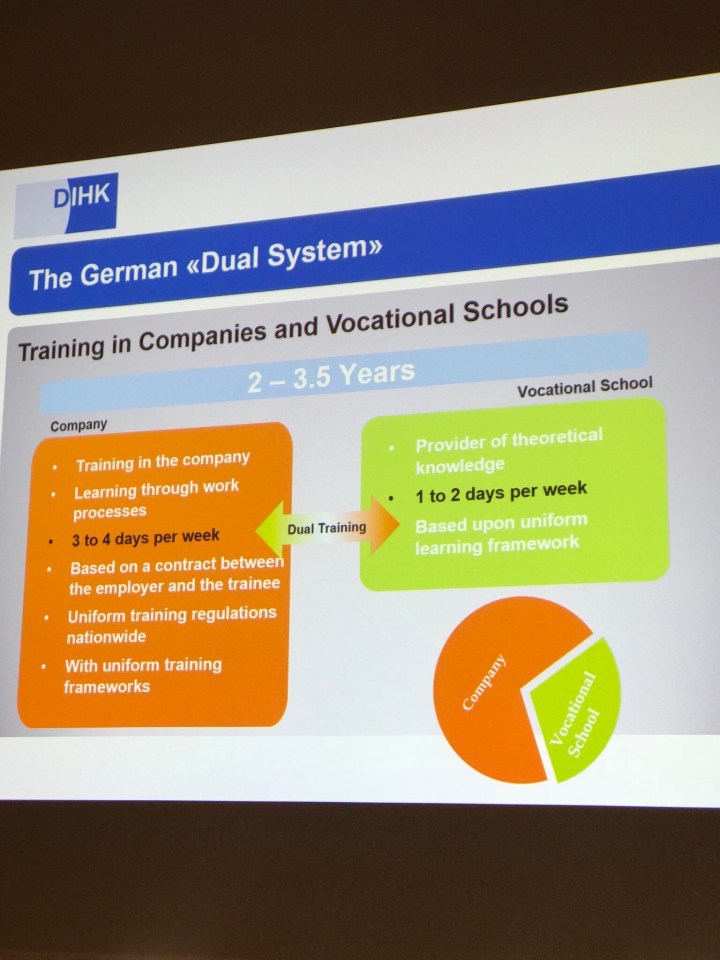

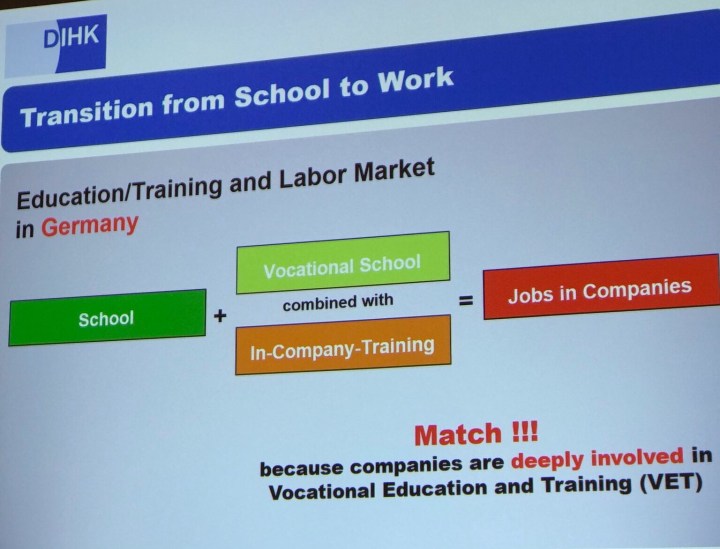

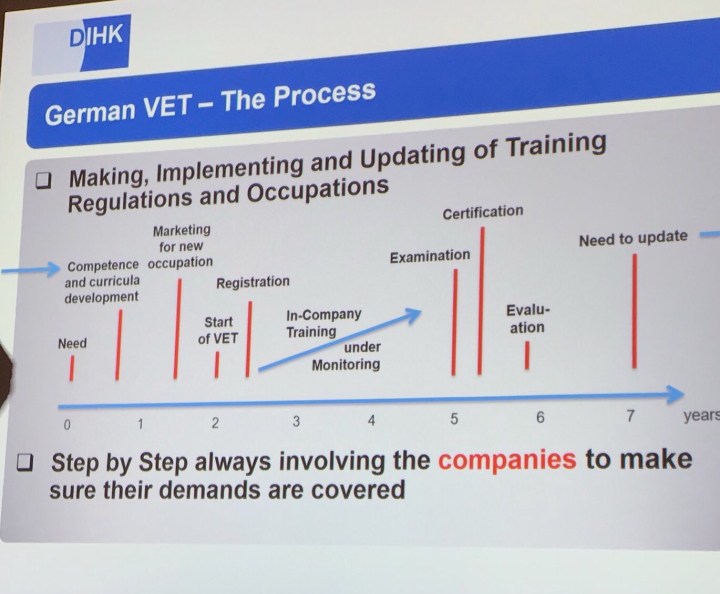

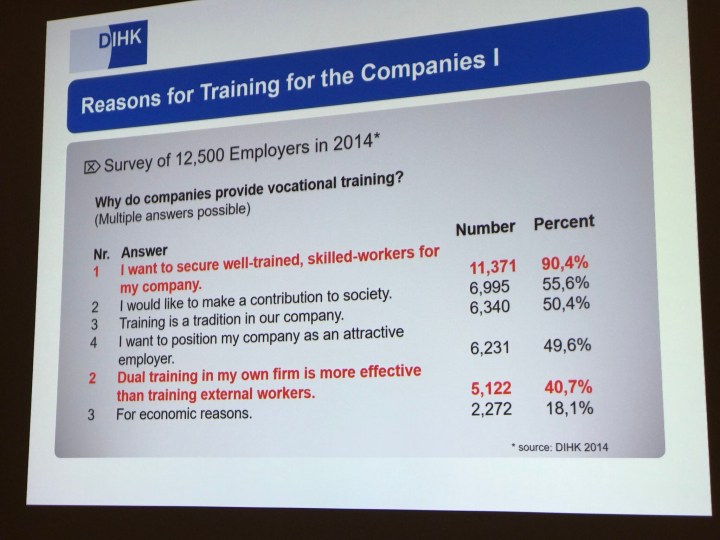

Today, while in Berlin, Germany, I was reminded that what I always say, “Once an Agriculture Science teacher and Career and Technical Education (CTE) Director, always a CTE guy. As I visited with Yorck Sievers of The Association of German Chambers of Commerce and Industry, I was reminded just how engrained the FFA motto of, “Learning to Do, Doing to Learn, Earning to Live, Living to Serve” is to making a positive difference in the lives of students by developing their potential for premier leadership, personal growth and career success through agricultural education. This is also engrained in my core values of how to educate young scholars. The Association of German Chambers of Commerce and Industry (Deutscher Industrie- und Handelskammertag, DIHK) is the central organisation for 79 Chambers of Commerce and Industry, CCI (Industrie- und Handelskammern, IHKs) in Germany. All German companies registered in Germany, with the exception of handicraft businesses, the free professions and farms, are required by law to join a chamber.

Today, while in Berlin, Germany, I was reminded that what I always say, “Once an Agriculture Science teacher and Career and Technical Education (CTE) Director, always a CTE guy. As I visited with Yorck Sievers of The Association of German Chambers of Commerce and Industry, I was reminded just how engrained the FFA motto of, “Learning to Do, Doing to Learn, Earning to Live, Living to Serve” is to making a positive difference in the lives of students by developing their potential for premier leadership, personal growth and career success through agricultural education. This is also engrained in my core values of how to educate young scholars. The Association of German Chambers of Commerce and Industry (Deutscher Industrie- und Handelskammertag, DIHK) is the central organisation for 79 Chambers of Commerce and Industry, CCI (Industrie- und Handelskammern, IHKs) in Germany. All German companies registered in Germany, with the exception of handicraft businesses, the free professions and farms, are required by law to join a chamber.

The FFA motto gives members 12 short words to live by as they experience the opportunities in the organization. Learning to Do, Doing to Learn, Earning to Live, Living to Serve. Learning by doing is also a cornerstone of the German education system. Whether someone wants to become a carpenter or a hotel concierge, she has probably gone though what is known as the dual education system. This system combines time spent in the classroom with work at a company. During our education research trip with Horizon Education Alliance, we learned about how Germany’s vocational education system pairs hands-on learning with classroom learning to give young people a leg up in the workforce. Most students graduate not only with a degree, but also with job experience and a deep knowledge of their trade. This vocational training offers a high degree of job security. The professional certifications issued to students at the end of their programs are well respected within their fields, and more than half of apprentices stay on as full-time employees at the businesses where they trained. They even get paid during their studies.

Check out a few slides from our meeting with Sievers:

During this time with Sievers we also learned that schools follow the companies and not the other way around. This training model is all about the future of the company, but the companies are not left alone. The companies need support. This is competency based education. The Chambers in Germany provide:

During this time with Sievers we also learned that schools follow the companies and not the other way around. This training model is all about the future of the company, but the companies are not left alone. The companies need support. This is competency based education. The Chambers in Germany provide:

- Organization

- Registration

- Examination

- Certifications on a national level

In this German model there are courses that cover more than 350 different occupations that are approved by the businesses and federal bodies overseeing the program. In Germany, they are truly walking the talk by facilitating students for “Learning to Do, Doing to Learn, Earning to Live, Living to Serve.”

2 comments